Lallemand Sourvisiae – Saccharomyces solution for sour beer production

Written by: Tim Matthews, Oskar Blues Brewery Many strategies have been used to create a sour profile in beer in craft breweries in recent memory. Kettle souring with Lactic Acid Bacteria is one strategy that has produced great beers with unique lactic acid profiles that vary from brew to brew. A critical bottleneck when using […]

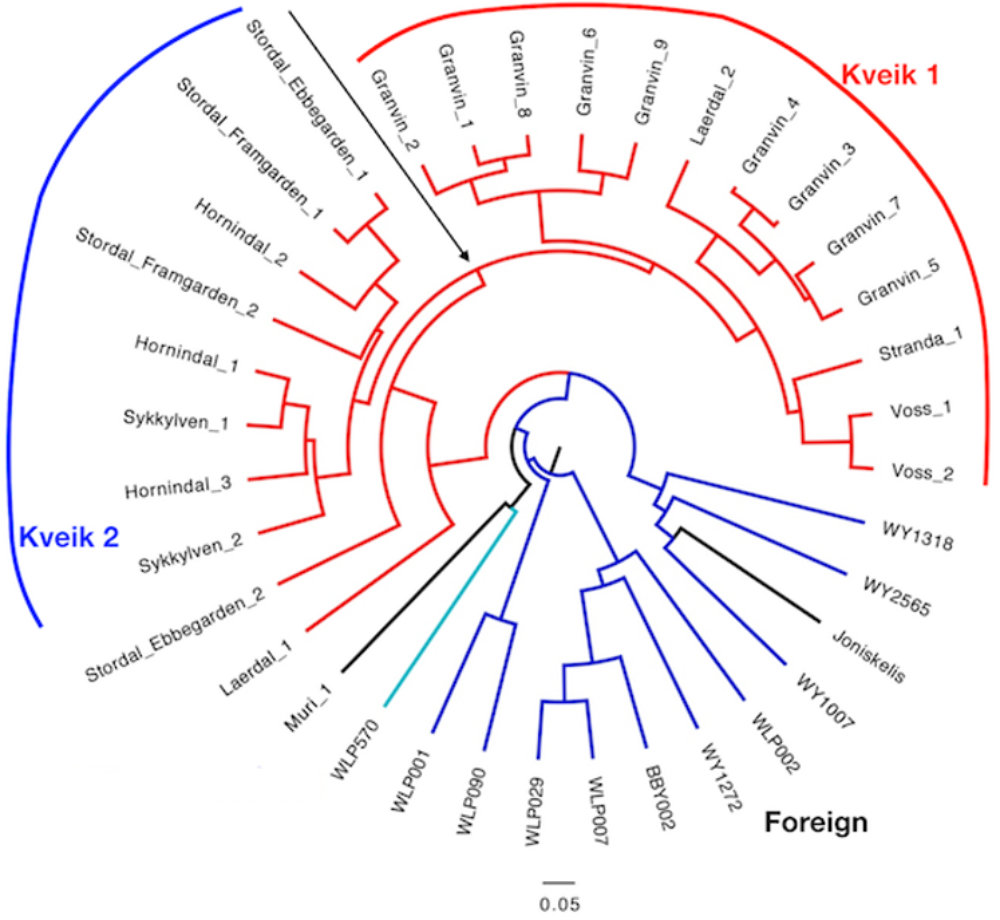

Kveik Yeast

Written by Matthew Peetz (Propagate Lab) and Dr. Ethan Tsai. While we obviously recommend checking out the recorded webinar that we provided for the CBG Summit, it’s understandable that the sound of our voices might bother some people. For that, we apologize for Ethan’s terrible delivery and countenance. Readers should consider this a companion piece […]

KEGS – BEST PRACTICES (PART 2 OF 3)

For Inspection, Handling, Washing, Filling, Maintenance and Repair Written for the Colorado Brewers Guild by Jon Graber, Micro Matic Packaging Division Kegs are a robust and durable package; therefore their inspection for safety and integrity as containers for quality draft beer is often neglected. It’s common for kegs to have suffered damage or years of […]

KEGS – BEST PRACTICES (part 1 of 3)

For Inspection, Handling, Washing, Filling, Maintenance and Repair Written for the Colorado Brewers Guild by Jon Graber, Micro Matic Packaging Division Kegs are a robust and durable package; therefore their inspection for safety and integrity as containers for quality draft beer is often neglected. It’s common for kegs to have suffered damage or years of […]

VDK & Warm Dry Hops…a love story

Christopher O’Connor – Director of Quality & Technical Brewing @ Sleeping Giant Brewing Company Introduction: One of the nice things about working for a contract brewery is that I get to see dozens of ways that people like to make beer. It’s like walking through an art gallery featuring dozens of painters. They all use […]

Common Safety Concerns for Colorado Breweries

Mike Clark from Olson & Olson has compiled a list of common safety concerns and is a good reference for breweries preparing for OSHA inspections. If you any questions regarding this report, you can contact him at 303-867-2070 or mike.clark@olsonandolson.com.

Brewing Up Some OSHA Enforcement – Are You Ready?

By Christopher Peterson, Partner, Fisher Phillips An increasing number of local breweries here in Colorado have been inspected within the last couple of weeks as part of OSHA’s continuing Local Emphasis Program (“LEP”) to reduce employee exposure to hazards associated with beverage manufacturing processes in general industry operations. As part of this LEP, OSHA is […]

Brewing Boots

For the long-term health of a brewer, either for yourself or for your employees, brewing boots are a top concern. This blog article will examine a few considerations that may impact your decision on boot style and features, and give a few recommendations for boots from CBG members. These recommendations have not been solicited for […]

LOCKOUT/TAGOUT (LOTO) STANDARD

The Lockout/Tagout (LOTO) standard covers the servicing and maintenance of machines and equipment in which the unexpected startup of the machines or equipment, or release of stored energy could cause injury to employees. Machines that start up unexpectedly while being serviced can cause severe injury or even death. Energy sources may include: electrical, mechanical, hydraulic, […]

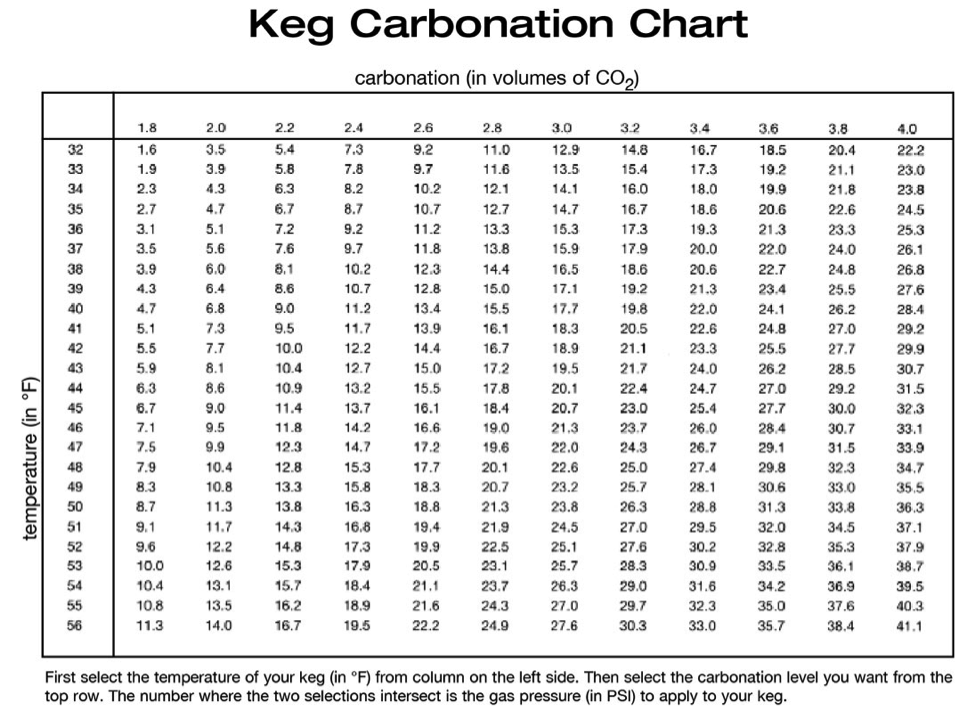

Let’s Talk Carbonation

First a bit about myself and the production facility I work in as I have found the size of the facility will dictate how and when you will add CO2. I have been working in a small brewery since the mid 2000’s only ever used a carbonation stone and the classic Zahm & Nagel for […]