First a bit about myself and the production facility I work in as I have found the size of the facility will dictate how and when you will add CO2. I have been working in a small brewery since the mid 2000’s only ever used a carbonation stone and the classic Zahm & Nagel for producing CO2 and measuring CO2 in solution. My production facility is a 10bbl system with no filtering and we rack into brite/serving vessels of the same size with just a bit of head pressure, say 5 pounds.

So how do we get there? For us carbonation starts at the end of fermentation. On day 5 of our fermentation we pull all blow off tubes from our fermentation vessels and cap our tanks to capture CO2. This begins the absorption of CO2 into liquid well before the racking process. By doing this at the time racking comes around some 10-14 days later most beers will have picked up 1.0- 1.7 volumes of CO2. Longer periods of maturation at cold temperatures can yield higher percentage of CO2 at racking but it is difficult to measure CO in solution below 1 volume in solution so exact amounts can be hard to quantify. Now onto the day of racking the exciting day when all your efforts turns into a drinkable product from the tap. We start with a clean and sanitized brite or serving vessel and push all sanitizer out of serving vessels with CO2 guaranteeing the tank is free of oxygen and saturated with CO2. At this point the racking begins. The fermentation vessel is kept under 5lbs. of CO2 head pressure throughout the rack and CO2 is supplied to the fermentation vessel through the CIP arm of the fermentation vessel at a rate of 32lbs to keep the tank at constant 5-10 lbs. of CO2 pressure thus pushing the beer into the serving vessel in a CO2 rich environment. In this manner a standard 10bl rack will take between 30-45 minutes and leave the beer in the serving or brite with 1.0 to 1.8 volumes of CO2. Once the beer is in the tank this is where the fun begins. To start it is crucial to build head pressure of 5lbs. of pure CO2. This blanket on top of the beer forces or traps, if you will, the CO2 you will be bubbling into the tank into solution instead of filling you headspace with CO2. By doing this I have found that CO2 times can be accomplished in 90 minutes on average. The CO2 provided to the carb stone does vary by stone manufacture and I have found that values between 22 and 32 psi are the answer. You will have to play with this in house to achieve your desired results. On most of my tanks 22psi provided to the carb stone with 5lbs of head pressure will bring a beer to 2.4-2.6 volumes of CO2 in 90 minutes. For some reason some of my tanks require 32psi for 90 minutes. All tanks are the same size 10bbls. only the manufacture of the stone if different.

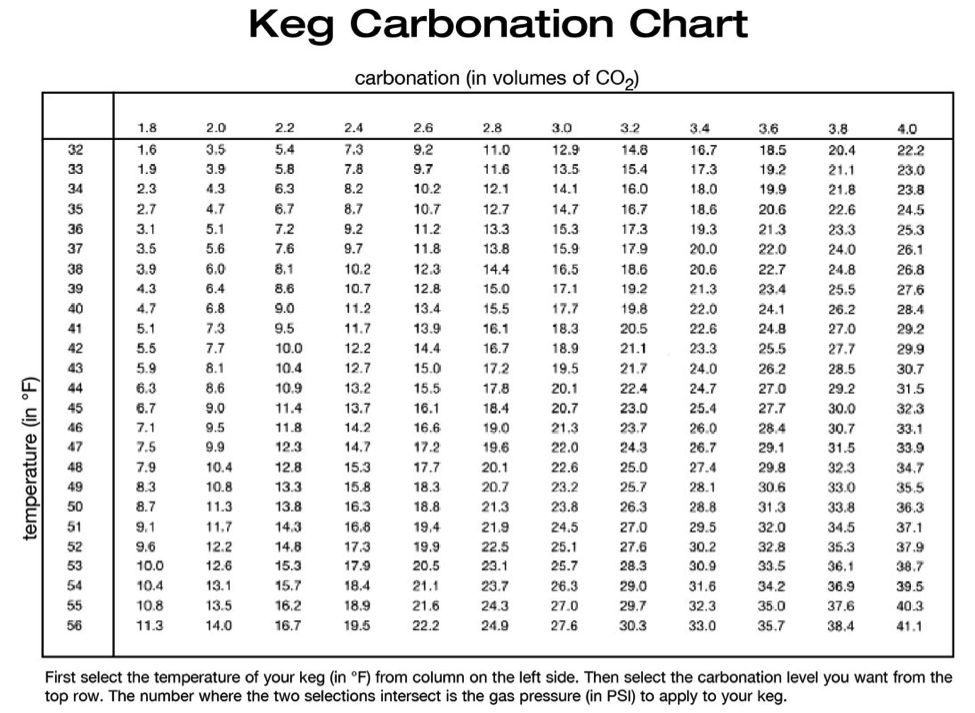

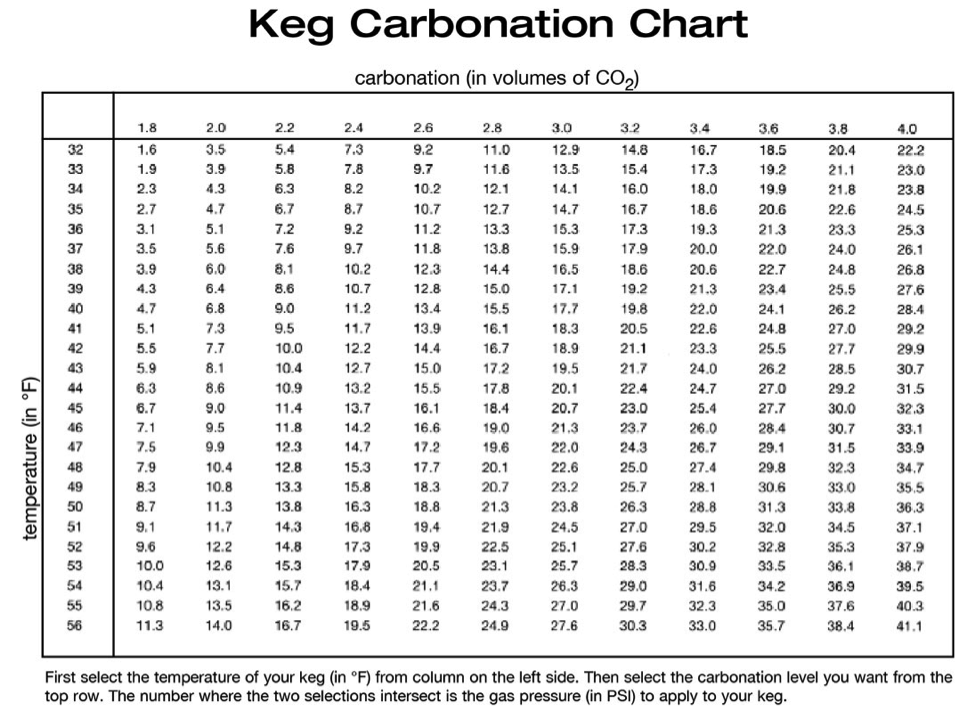

Below I have included the classic carbonation chart and I’d highly recommend keeping it in your serving vessel room or close to your brite tank. This chart is wonderful in illustrating the relationship between cold and carbonation. The key point here is a beer that is successfully racked in to brite or server must be cold, ideally in the 30’s to be properly carbonated otherwise the pressures needed to successfully carbonate will exceed the Pressure Relief Valve on your serving vessel making carbonation impossible until the correct temperatures are reached.

Hope this helps and remember…… Brewing is Love.

Written by Greg Matthews, head brewery Platt Park Brewing – Denver, CO