For the long-term health of a brewer, either for yourself or for your employees, brewing boots are a top concern. This blog article will examine a few considerations that may impact your decision on boot style and features, and give a few recommendations for boots from CBG members. These recommendations have not been solicited for in any way.

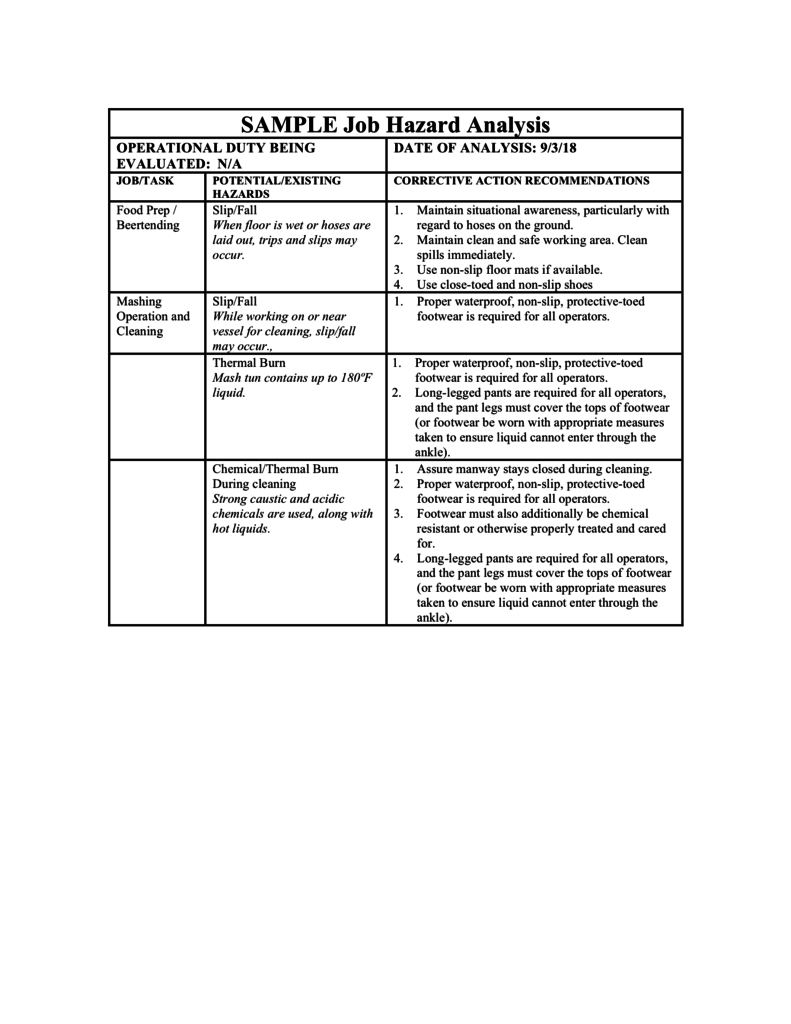

Different tasks in the brewery have their own sets of hazards, and thus different sets of requirements for footwear. Below is a sample hazard analysis in regards to footwear of various tasks, and the appropriate features to consider to mitigate those hazards (adapted from the Job Hazard Analysis section of Pikes Peak Brewing Co.’s Safety Program):

Drawing from these examples, we can see a few patterns and points of note. Firstly, footwear safety regarding slips, chemical splashes, and high temperature liquids goes beyond the choice of footwear. Controls should be in place to minimize exposure to these hazards, regardless of what shoe or boot is used. Secondly, how the footwear is worn, and with what additional clothing / safety equipment it is paired is also important. Lastly, though not explicitly stated, if someone is merely walking through an area where these hazards may exist, they should be held to these same standards or otherwise kept separated from the hazards.

There are also some basic safety features that should be noted: Non-slip soles, waterproof and high enough to avoid splashes / be covered by pants, and safety-toe (composite or steel). A quick aside: boots should always be covered by pants to prevent them from filling up with chemicals or hot liquids; if they cannot be for some reason, gators should be worn to cover the tops of boots. Not mentioned above, if your brewery packages in glass bottles, midsole protection or a puncture-proof plate may be important. Additionally, if dealing with chemicals during CIP, chemical resistance should be a factor. Also incredibly important is comfort. Arch support and inserts are very important to the long-term health and happiness of brewers.

Oftentimes brewers opt for the best general footwear to address these needs broadly, though some breweries opt to provide two sets of footwear – comfortable, slip-resistant and safety-toed boots for general wear, and waterproof / chemical resistant safety-toed boots to change into for CIP cycles. While ordering two pairs of boots for each brewer is a greater upfront cost, they boots will last longer when they are used for their intended jobs, and safety will be better-ensured. An uncomfortable boot can also be made tolerable using comfort liners or inserts.

Given these considerations, here are comments from fellow Colorado Brewers:

- Top Concern – Waterproof, followed closely by non-slip.

- Only breweries that bottle are concerned about punctures on the sole.

- Most breweries do not have specified requirements for how to wear boots. Some require above the ankle. It is highly recommended that all breweries set forth a requirement that prevents liquids from entering the boot – either ankle-coverage combined with long boots, gators, or calf-high and covered.

- Breweries are evenly split between providing boots at a regular interval, or providing a stipend and allowing employees to purchase boots of their choosing. All breweries surveyed provide boots through one of these methods.

Lastly, here are some specific recommendations:

Servus Economy Steel-Toe – Cost: Under $35. Chemical Resistance: Good. Non-Slip: Good. Waterproof: Yes. Comfort: Poor. Recommended for cleaning only.

- Honeywwell / Xtraftuf Neoprene Boots – Cost: $100-$150. Chemical Resistance: Very good. Non-Slip: Very good. Waterproof: Yes. Comfort: Very Good. Recommended for cleaning, packaging, brewing. Fairly comfy with the cork liner.

- Keen Workboots (American Made) – Cost: Under $120-$220. Chemical Resistance: Very good (if leather parts are maintained. Non-Slip: Very good. Waterproof: Yes. Comfort: Excellent. Recommended for all tasks, all day. Anecdotally, it is important to get the American-made boots.

- Shoes for Crews Workboots (Guardian, Sentinel, Bullfrog) – Cost: $50-$100. Chemical Resistance: Good. Non-Slip: Excellent. Waterproof: Yes. Comfort: Good. Recommended primarily for cleaning. Shoes for Crews also make great non-slip workboots that are not chemical resistant, but are very comfy for all-day wear when brewing, packaging, or working front-of-house.

- Dunlop Purofort Boots – Cost: Under $100-$200. Chemical Resistance: Excellent. Non-Slip: Excellent (when broken in). Waterproof: Yes. Comfort: Very good. Recommended for all tasks, especially cleaning and brewing. Recommended with a comfort liner.

- Doc Martin Wellington / Industrial Work Boots (composite toe) – Cost: $120-$180. Chemical Resistance: Very good (if leather parts are maintained). Non-Slip: Very good. Waterproof: Yes. Comfort: Excellent. Recommended for all tasks, all day.

A final quick note – other industries have a longer history dealing with the challenges that brewers face in regards to their footwear. In particular, fishermen and oilfield workers have excellent reviews and recommendations for non-slip, waterproof boots. If these do not satisfy your needs, try looking for boots catering to those industries!

Written by Alan Windhausen – Head Brewer – Holidaily Brewing Co.