Written by: Tim Matthews, Oskar Blues Brewery

Many strategies have been used to create a sour profile in beer in craft breweries in recent memory. Kettle souring with Lactic Acid Bacteria is one strategy that has produced great beers with unique lactic acid profiles that vary from brew to brew. A critical bottleneck when using this method is the occupancy in the brewhouse. Kettle occupancy can last up to a few days based on the viability, vitality and species of the culture used to produce the lactic acid. Many breweries have been able to optimize the fermentation conditions of the souring culture in the kettle to create the desired sour profile in as little as 2 hours; the culture needs to be pitched in a predictable and time compressed manner to obtain and maintain that capability. These production challenges created the need for a solution that operates similarly to a typical ale fermentation (50F-72F optimum fermentation temperature range) and pitch rate (50-100g/hl) which does not extend the kettle residence time and is flexible with production scheduling. Additionally, as a strain of Saccharomyces cerevisiae, this yeast is susceptible to a brewery’s standard CIP/SIP process.

Lallemand Sourvisiae has been utilized by breweries to address these challenges. Sourvisiae is a genetically engineered strain of S. cerevisiae yeast that can be handled and managed like any other S. cerevisiae strain in the brewery, including the cleaning and sanitation processes required with yeast rather than with lactic acid bacteria. The metabolism of this strain is very similar to that of most standard ale strains, but via an inserted lactate dehyrogenase enzyme it can simultaneously produce lactic acid and ethanol. Relying on Sourvisiae as the primary source of lactic acid, brewers are able to avoid the by products from other kettle sour cultures, such as butyric acid, isovaleric acid and Tetrahydropyridine, or THP, which is described as Cheerios, mousy, or urine.

Alternatively, Sourvisiae can be co-pitched with other species of Lactobacillus bacteria in the kettle to quickly and reliably produce a large quantity of lactic acid synergistically with the other positive flavor-active metabolites produced by other bacteria during the souring process.

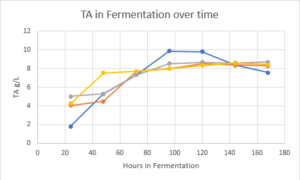

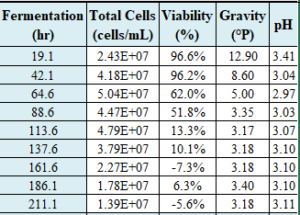

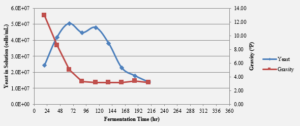

Sourvisiae has high lactic potential upon first use. Lactic acid production is 8-12 g/L in fermentation (see Figure: TA in fermentation over time), yet the use of a propagation or step-up (see Supplementary Box: propagation) has been demonstrated to keep the lactic acid production at lower levels of between 7-9 g/L. Lactic acid production was seen to peak between 90-110 hours into fermentation. It is also important to note that the yeast drops in viability drastically once there is no more sugar to metabolize (as seen below), thus re-pitching a culture is not recommended.

Propagation

The Yeast has also proven to be effective using a 24 hour propagation.

- 10 gram per barrel of target batch pitched into 5 barrels of 15-17 plato wort at 68F that is saturated with oxygen (>25 ppm O2) after chilling during fermenter fill. (ie. 1000 grams pitched in to 5 bbl for a 100 bbl fermentation)

- Example below is 100 bbl batch with starting gravity of 15 plato.