Cover your eyes, we’re about to get super nerdy up in here.

PCR Testing in Your Brewery

By Eric Larkin, Owner and Head Brewer at Cohesion Brewing Co. and John Giarratano, Owner Inland Island Yeast Labs

Polymerase Chain Reaction or PCR is a technique for amplifying a particular gene of interest millions or billions of times. This DNA amplification can be accomplished with only a few biological ingredients and changes in temperature to activate the necessary processes. To understand this technique in simple terms, it’s important to understand a few definitions.

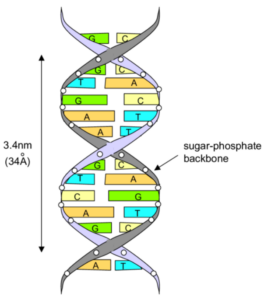

Deoxyribonucleic Acid (DNA) is a polymer of two nucleotide chains, in the shape of a double helix, containing the genetic information for the function, growth, and reproduction of all known organisms.

DNA Polymerase is an enzyme, essential to DNA replication, that “reads” the existing DNA to create new strains of DNA.

Primers are short pieces of single stranded DNA that attach or adhere to the segment of sample DNA to be amplified.

A dozen college lectures could be devoted to explaining in detail how each of the processes in PCR takes place, but for our purposes, PCR takes place in three steps.

1. First, a sample is heated to denature or break up the two strands of the DNA molecule.

2. Next, the sample is cooled so that the primers will attach to the targeted gene on the DNA template.

3. Finally, the sample is heated so that DNA polymerase can begin adding nucleotides to the primers in the sequence dictated by the DNA. This process is then repeated for 30-35 cycles until the DNA of interest is amplified. If the target gene is not present, then nothing will be amplified and the instrument will give a negative result.

PCR has many applications in fields such as medical, forensics, biotechnology, and biology. For the first 30 years after its development in the 1980s, PCR remained cost prohibitive to most businesses outside of healthcare and research institutes. However, within the last 10 years, several platforms were developed that have allowed breweries access to PCR technology.

Before PCR, quality control testing in breweries was limited to biological detection using growth medium and agar plates. While these methods are great at detecting the presence of living organisms in a sample, they can be labor intensive and require several days to incubate. Thus, screening for contaminants using a growth medium is not a great option when immediate answers are necessary. Imagine everyone’s frustration when the QC department says it’s going to take four days before a decision can be made on a particular batch of beer with a suspected contamination.

Along comes PCR, and suddenly breweries have the ability to detect spoilage organisms within hours of sample preparation. Most of the less expensive and therefore more approachable options are End Point PCR. In this application, the target DNA from a spoilage organism is amplified in a sample, and the resulting DNA is placed on a cassette that reports the presence or absence of the spoilage organism.

These days brewers also have the option of Real Time or Quantitative PCR. With this technology, the amplification from each cycle can be seen linearly in a graph. This level of detection allows for the determination of concentration of a spoilage organism as well. Along with fluorescent amplification of boud primers, QPCR can use temperature to test affinity of bound molecules, and therefore providing proof that the correct gene was targeted and amplified.

Although current PCR platforms are capable of fast, reliable and verifiable identification of spoilage organisms in beer, it is important to recognize that PCR is only capable of answering the questions that it is asked. By running a sample using PCR you are basically asking the machine “Does this sample contain the gene that I’ve targeted with my PCR primer”? However, it is NOT asking “Is this sample free of contamination”? If a brewer or QC technician runs a sample for diastaticus and gets a negative result, that does not mean that the sample is free of beer spoiling wild yeast.

Most bacterial PCR primers that are designed for the brewing industry are only targeting a gene that is known to exist in hop resistant lactobacillus strains. A negative result for one of these tests only excludes a small subset of lacto strains. In order for PCR to verify a sample is completely free of contamination, it would have to target a gene for every spoilage organism known. It is also important to recognize the size of the sample that is being tested. In many PCR platforms, the size of the sample that is actually being loaded in the PCR tubes is less than .1 milliliters. From a sample that small, it would be impossible to detect down to one cell per mL. If screening for all organisms is required, plating on growth mediums is suggested.

So how does knowing all of this help you in a brewery? First, knowing what you’re looking for can influence your purchasing decisions. Traditional plating has a low cost of entry, but requires labor hours and days for incubation. PCR can be a solution for quick answers to contamination risks, but come with a very high cost of entry and inherent gaps in their detection limits. Developing a Quality Control platform that includes both methods (PCR and Plating) is obviously the most robust approach, but 3rd party labs can be utilized when additional resources are required.

PCR can be a very powerful tool for a brewer, but it can also come at a labor and capital cost that may not be available for every brewery. A number of cheaper and potentially easier options are available to track beer from a quality perspective in your breweries. Building a packaged beer library can be one of the more valuable tools, that may take up some physical space, but comes at a minimum cost. Storing packaged beer in a room temperature environment for the expected life of the beer can be a helpful tool to know if there are any long term changes to the quality of the beer after it leaves the brewery.

Exploring a setup to use a variety of agar plates that can test for a range of microorganisms, is also a much lower cost to entry from a lab equipment standpoint, and should be considered alongside PCR in most environments to begin with. While making plates in-house can reduce the cost significantly, it can be beneficial to check if any local labs, yeast suppliers, or other breweries are willing to sell the pre-made plates. Be sure to discuss with those sources the date of the agars, as some can become less effective at growing the microorganisms if they have been sitting for too long.

Developing a relationship with your yeast supplier can be one step towards eliminating the variables that go into where possible contaminants can enter the scene. There are yeast suppliers who are running PCR on their pitches before they are sent out to ensure a pure pitch, but asking for those results and understanding exactly what the results are for your pitches can be valuable. It is also likely that the yeast lab you are purchasing from has all the necessary tools to help pinpoint a problem related to micro activity, and if your brewery is not set up to detect those organisms confidently, they may be willing to help out on that front. It’s always worth starting the conversation with your yeast supplier to know what they’re capable of helping with.

Overall, PCR has many valuable applications in a brewery setting, but there are a plethora of factors that must be considered before moving forward with installing this technology. While it can provide pinpoint accuracy in some cases, knowing the bigger picture can help you make the best decisions for your quality program.

Interested in reading more about all things nerdy in the brewing world?

Check out the articles: The Art & Science of Hazy Beer and Implementing the Scientific Method in Your Brewery Part 1