By Robert Meehan Ph.D., Head Brewer at Living the Dream Brewing

Introduction:

In part one of this series, you were introduced to the steps of the Scientific Method. Science, however, is an ever complex and fickle endeavor. The ability to control and repeat your processes will mean your conclusions have more validity and your actions are supported by un-biased outcomes.

Variables, Constraints, and Repeatability:

The most important thing about using science in your brewery is getting started. Don’t get overwhelmed with perfection. Once you begin the process, you’ll gain more experience asking questions and running experiments. As you dive deeper though, if you want to have more reliable results and confidence in your decisions, understanding variables, constraints, and repeatability is key.

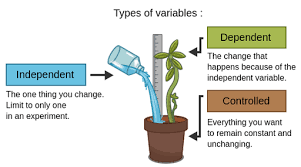

Variables are items that can change or be adjusted. The two primary types you affect are independent and controlled variables. Independent variables are ones that you alter on purpose. If you are looking into the effect of mash time on starting gravity, the length of mash would be your independent variable. Controlled variables are things you want to keep constant during your experiment. In the previous example, controlled variables would be the mash tun you use, mash temperature, volume of water, pounds of grain, etc. Ideally, you only have one independent variable, and the rest would be controlled. This is to help connect whatever you see in your experiment back to the variable you purposely changed. For most breweries, you’re likely not swapping out your mash tun in between brews, but depending on what beer you’re making, you may have a different mash temperature or grain to water ratio. If you change the length of your mash time and the mash temperature, and your starting gravity goes down, you can’t be certain whether that was due to the time, temperature, or a combination of both. The third type of variable is the dependent variable, which is the change that occurs due to the independent variable. This is the observed difference from your experiment. Designing your experiments to focus on one independent variable, and minimizing the change in others, is the next step in your scientific journey.

Variables are items that can change or be adjusted. The two primary types you affect are independent and controlled variables. Independent variables are ones that you alter on purpose. If you are looking into the effect of mash time on starting gravity, the length of mash would be your independent variable. Controlled variables are things you want to keep constant during your experiment. In the previous example, controlled variables would be the mash tun you use, mash temperature, volume of water, pounds of grain, etc. Ideally, you only have one independent variable, and the rest would be controlled. This is to help connect whatever you see in your experiment back to the variable you purposely changed. For most breweries, you’re likely not swapping out your mash tun in between brews, but depending on what beer you’re making, you may have a different mash temperature or grain to water ratio. If you change the length of your mash time and the mash temperature, and your starting gravity goes down, you can’t be certain whether that was due to the time, temperature, or a combination of both. The third type of variable is the dependent variable, which is the change that occurs due to the independent variable. This is the observed difference from your experiment. Designing your experiments to focus on one independent variable, and minimizing the change in others, is the next step in your scientific journey.

As you get a better handle on your variables, identifying your constraints will be the next hurdle to address. Constraints are the limitations in your process or availability of resources. The weather outside can impact your mash temperature even though you do your best to keep it constant. Additionally, you may want to test carbonating at lower temps, but notice that your glycol chiller struggles to get your brite tank cold enough. Unfortunately, we can’t control the weather and most breweries can’t afford to buy three new chillers to compare. These are all constraints that will limit how accurately you can interpret your experiments. They don’t mean that your test is a waste of time, but it does mean you may need to take everything with a grain of salt (also a great name for a Gose).

The last major component in taking your science to the next level is repeatability, which is being able to run your experiment multiple times to look for an exact, consistent pattern. Since there are so many variables and constraints in flux, we can’t take one trial as clear proof of anything. As a good rule of thumb, if you run your experiment numerous times and get at least three matching outcomes, that is a strong indication that what you observe is legitimate. So, next time you want to test how long it takes to carbonate beer; use the same brite tank, run your test on the same beer, set the same temperature, use the same instrument to check your carbonation level, and track your time on the same clock. Then, do it again, and again, and…again for good measure. You may notice subtle changes in how long it takes, however, if it always takes less time, then you can feel confident that it is truly faster. It’s important to know that repeatability and accuracy are two very different things. Your methodology can yield repeatable results but, due to unknown variables or constraints, those results may not be accurate. Coming up with new ways to test your theories and changing up your experiments can aid in getting repeatable and accurate results.

The last major component in taking your science to the next level is repeatability, which is being able to run your experiment multiple times to look for an exact, consistent pattern. Since there are so many variables and constraints in flux, we can’t take one trial as clear proof of anything. As a good rule of thumb, if you run your experiment numerous times and get at least three matching outcomes, that is a strong indication that what you observe is legitimate. So, next time you want to test how long it takes to carbonate beer; use the same brite tank, run your test on the same beer, set the same temperature, use the same instrument to check your carbonation level, and track your time on the same clock. Then, do it again, and again, and…again for good measure. You may notice subtle changes in how long it takes, however, if it always takes less time, then you can feel confident that it is truly faster. It’s important to know that repeatability and accuracy are two very different things. Your methodology can yield repeatable results but, due to unknown variables or constraints, those results may not be accurate. Coming up with new ways to test your theories and changing up your experiments can aid in getting repeatable and accurate results.

Now that you know how to answer all those lingering questions, you can start your journey to more efficient processes, less inconsistency, and higher quality beer. It’s important to remember that any science is better than random action, but well controlled scientific design is what will separate you from the pack. Just always keep trying and learning. In the next installment of the series, statistical measurements will be discussed. Measuring your data appropriately allows you to compare apples to apples and make well informed decisions.

To learn more about the limitations of experimental design, this article offers a great in-depth breakdown of common constraints

https://helpfulprofessor.com/research-limitations-examples/

For a deeper understanding of repeatability vs. reproducibility, check out the following information:

https://www.isixsigma.com/methodology/repeatability-vs-reproducibility-whats-the-difference/