The ins and outs of draft line cleaning and why it is crucial to beer quality.

Introduction

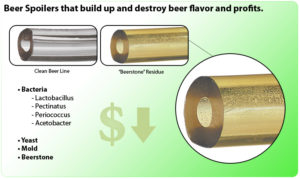

Proper cleaning and maintenance of your draft system is just as important as the various CIP methods employed in production. If you neglect your draft system, your beers will suffer! Carbonation, off-flavors, and the appearance of the beer can all be affected by dirty draft lines. The following is a step by step process to ensure your draft lines are sparkling clean and will not have a negative impact on the flavor of your beer.

Various methods of draft line cleaning

There are two main draft line cleaning techniques; static and recirculation. The recirculation method is certainly superior to static line cleaning but, because of the additional cost and different draft system designs, this option may not be practical in every situation. The two methods both have their unique pros and cons and, depending on your draft system or cleaning needs, one may be better suited than the other (it just isn’t practical to set up a recirculation pump in the middle of service when tapping a new beer).

The How

All methods of draft line cleaning requires some sort of an alkaline solution, a sanitizer, and equipment needed to deliver those chemicals into the draft system. As with brewing equipment on the production side of a brewery, all areas in contact with beer of a draft system need to properly cleaned before they can be sanitized. Chemicals such as Powdered Brewery Wash (PBW) is an excellent, safe detergent for all types of line cleaning.

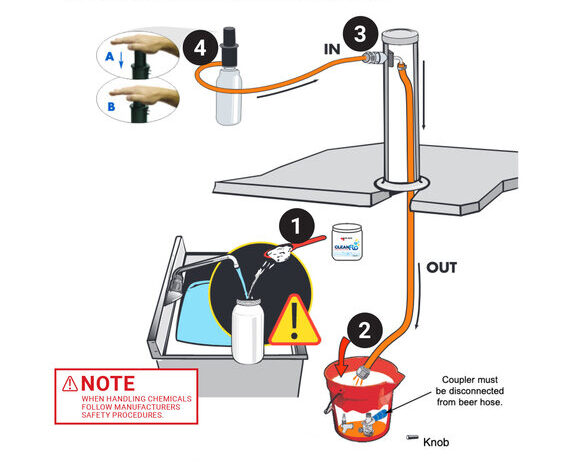

With static cleaning the only equipment one needs is a cleaning pot. To start, fill up the cleaning pot with warm water and flush out all beer from a line. Next, fill the cleaning pot with the correct ratio of PBW (or equivalent) and warm water (not too hot!) and run through the line until the PBW solution flows through the faucet. I say “not too hot” because you do not want run the risk of personal injury or damaging a component of the draft system; pulling water off of the HLT is probably not the best idea. Keep the coupler attached to the cleaning pot for the 20 minutes need to properly clean the line. Note: If you uncouple the coupler from the cleaning pot your cleaning solution will leak from the system and you will have areas of the draft line not in contact with your alkaline solution.

After the cleaning cycle, rinse all traces of your solution from the cleaning pot, fill with water and then add your sanitizer into the cleaning pot (always add chemicals to water, never water to a chemical – this is extremely important when using caustic). Repeat the process of pushing your sanitizer through the line. Use a ph strip to test when the sanitizing solution has filled the draft line (or you can use the “gritty” test with your fingers if using Saniclean as a sanitizer). Let the sanitizer sit in the line per the manufacture’s recommended time and then rinse with cool water before hooking the keg back up to the draft line.

The use of a recirculating electric pump requires a bit more equipment and set up time but allows one to clean multiple lines simultaneously, the ability to “push” your cleaning chemicals against the normal path of dispensing beer (the flow direction should be alternated with each cleaning), and, because the cleaning solution is constantly in motion and the ability to reverse the flow, is far more effective than using a static cleaning pot. An additional benefit is the ability to clean your faucets while the draft lines are being cleaned. *Faucets will need to be removed after static cleaning, adding more time to the process.

When setting up a recirculating pump the system needs to be connected in a loop which will require the couplers to be attached to one another using a special coupler adapter and the faucets removed and their associated shanks connected via a cleaning jumper line. The last beer line in the loop will be connected to the cleaning solution “return” line (more of that to follow).

The next step is to take a 5 gallon bucket filled with warm water. Place the “supply” hose of the pump into the bucket and set the “return” line (see above) into the draft system drain. Turn on the pump (be sure that all FOBs are disengaged) and flush all beer out of the system with the warm water in the bucket. Once the lines are rinsed of beer, refill the bucket with warm water along with your cleaning detergent and place the “return” line into the bucket, completing the loop. Run the pump recirculating detergent throughout the system for 15-20 minutes. This is a perfect time to disassemble your faucets and soak them in their own cleaning solution, *Remember to use a brush to assist in this process.

After the cleaning cycle is complete, discard your cleaning solution replacing with warm water to flush out detergent from the system (put the “return” line back into the drain for this). The next step is to refill the bucket with water, add your sanitizer, complete the loop by inserting the “return” line back into the bucket, and cycle sanitizer throughout the system. Flush out the sanitizer from the system using cold water and check with a pH strip that the lines are free of sanitizer before hooking kegs back up.

Additional notes

• If pneumatic beer pumps are being used the gas supply to the pumps will need to be turned off prior to using a recirculating pump and their flow setting will need to be changed to allow the reversed flow of cleaning solution (backflow setting).

•It is important to turn off any glycol chillers associated with your draft system when cleaning; otherwise the chiller will cool down your alkaline solution below its effective temperature range.

•Draft systems that employ split lines may require additional equipment and steps not covered above.

How frequently do you need to clean your lines?

Draft lines must be cleaned using one of the above methods every two weeks for proper maintenance. You don’t skip cleaning a tank so don’t skip cleaning your lines! While we employ a recirculating electric pump for our line cleaning, we are frequently tapping new beers between cleaning cycles. Every time we tap a new beer (brand) we use the cleaning pot method before serving the new beer. That line will receive the recirculating treatment on the following line cleaning day. You never want to “push” beer brand “A” out of the line with beer “B”.

It is also important to switch up the chemicals used in your cleaning. Every quarter we rotate between a strong caustic and an acid cycle. For the acid cycle we use Acid Cleaner #6 from Five Star as this is great for removing beer stone. ALWAYS be sure that proper, safe chemical handling is used when working with caustics and acids (remember to wear googles and gloves!).

While couplers, FOBs, and beer pumps are cleaned using the described methods you always want to set aside a couple times a year when you completely disassemble those devices and thoroughly clean them. Faucets should be taken apart and cleaned every two weeks when you perform your regularly scheduled line cleaning.

The information above is just the tip of the iceberg for proper draft system maintenance. For more information, I highly recommend the “Draught Beer Quality Manual” published by the Brewers Association.

This post was written by Chad Pieper of Upslope Brewing Company, Boulder, CO