By: Jose Quinones, Head Wrench at 6 & 40 Brewery & Taproom in Lakewood, Colorado

Are you ready to talk nerdy?

We’re about to dive into how malt sieve analysis helps maximize mill efficiency, so hang on tight.

When was the last time you adjusted the gaps on your malt roller mill? What data are you collecting to help you adjust the gap and maximize your mash extract? Completing regular malt sieve analysis helps to maximize the efficiency of the mash while preventing slow or stuck runoff.

Maintaining consistent brewhouse efficiency is critical to the overall quality of your beer, and it helps to prevent costly overruns caused by wasted raw materials and/or brewer labor hours. When combined with a review of malt COA, malt sieve analysis is a great tool for ensuring consistency.

Malt sieve analysis is an easy process that requires very little specialized equipment to complete. A small sample of crushed grain is added to grist sieves which are then agitated for a set amount of time, after which the contents of each sieve are weighed and analyzed.

Per the American Society of Brewing Chemists:

A grist sieve is a standard steel or brass instrument used for sifting malt grist during brewing. The grist sieve commonly comes in a circular shape of various diameters with a solid outer ring and fine mesh sieve interior. After the malt milling process is complete, the malt grist is analyzed by manually sifting it through a series of grist sieves that all retain different-sized pieces of grist.

While there is a wide variety of mesh sieve sizes available, the most commonly used configuration is a set of 8” diameter screens stacked in decreasing order of coarse to fine as follows:

#14 Mesh

#30 Mesh

#60 Mesh

Pan

Larger production breweries using a 6-roller mill may add a #10 Mesh to the top and a #100 Mesh to the bottom of the stack for further sifting and fine-tuning.

Other tools needed to complete the malt sieve analysis are a digital scale, a piece of blank paper, and a timer.

The setup for the test is relatively simple:

– Measure and record the mill gap(s) using a feeler gauge

– Collect and crush a 100g sample of the malt

– Pour the malt sample into the top mesh sieve (#14), place the cover on the stack, and set a three-minute timer

– Slide the sieves back and forth on a smooth surface for three minutes, lifting and tapping firmly on the tabletop every fifteen seconds (see video example)

– Collect the particles from each sieve, recording the weight of each and emptying the contents onto the blank sheet of paper

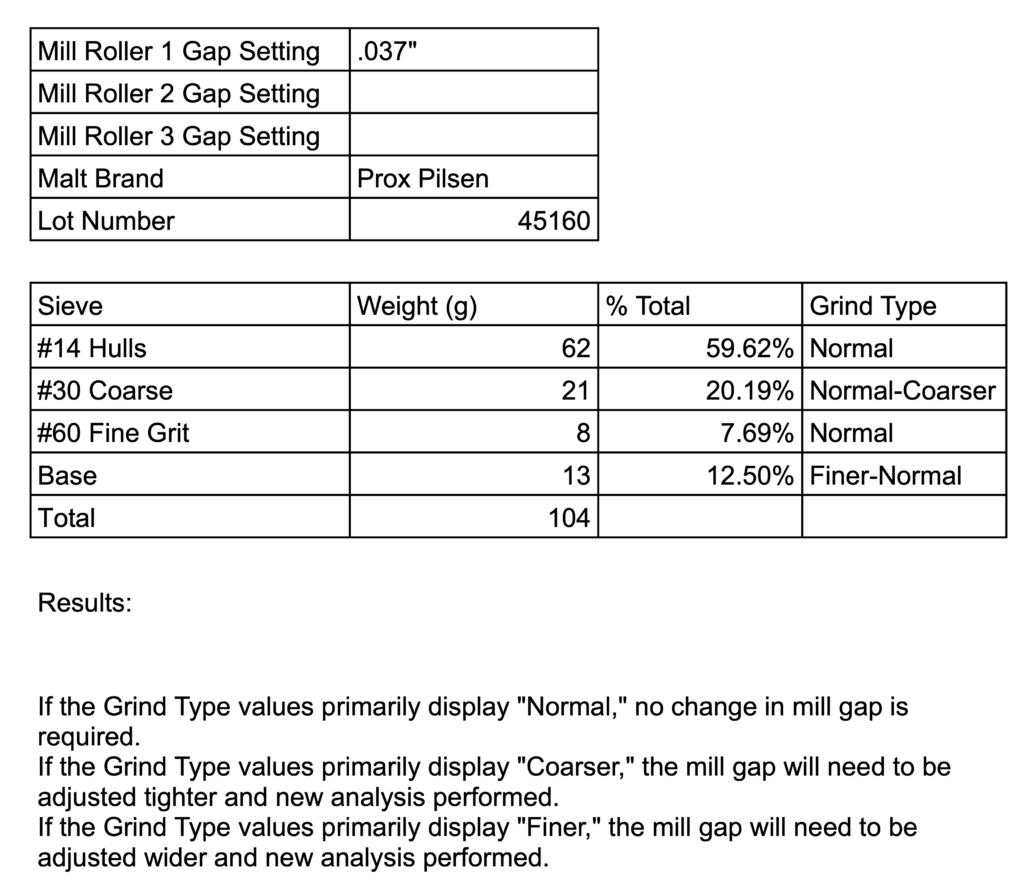

– (Optional) Record the weights of each sieve on the handy spreadsheet below to determine whether any gap adjustments need to be made

You can download the google spreadsheet here.

Once the malt sieve analysis has been completed, make any necessary adjustments to the mill gap(s) and repeat the test until the results are within the range needed for your brewhouse.

Typical values for mill settings are as follows:

A final step, not always included in this process as outlined by ASBC, MBAA, and the Craft Maltsters Guild, is a quick sensory analysis of the crushed particles from each screen. The #14 sieve results should primarily be hulls, with the next two screens having a lesser amount of bitter hull material. The pan should dissolve quickly in the mouth and taste sweet. If the pan tastes bitter, the mill could be crushing too much hull material and may need to be adjusted wider.

At our brewery, we print every malt sieve analysis and staple them to the malt COA. We have this information readily available when reviewing wort extract from batch to batch. If we complete a one-off seasonal brew using malt from a different supplier, we may find ourselves sacrificing a few hundred grams of malt to complete sieve analysis, but that’s a small price to pay to ensure consistency of mash extract and a reasonable runoff time.