A guide to creating a Hazard Communication Program to ensure chemical safety in your brewery.

As we all know being a brewer is really just being a glorified janitor. When you’re making the perfect bug food, you better be sure that the only bugs are the ones you want. Because cleanliness is so important, we turn to science to help us out. Chemicals are used to make sure we have a system that will be spic-and-span for our wort and yeasties, making man’s greatest achievement to date: delicious, delicious beer!

Since chemicals are used, it is important (and the law) to protect your staff and visitors. A Hazard Communication program plan should be designed to ensure that the hazards of chemicals used are communicated to affected employees, along with safe handling and protective measures. Implementing these measures reduces the likelihood of a chemical incident that may harm staff.

The program fulfills Occupational Safety and Health Administration (OSHA) regulatory requirements in 29 Code of Federal Regulations (CFR) 1910.1200(h)(1) and 1926.59.

This program should cover all hazardous chemical operations within the brewery, including both the front of house and the back of house. Hazardous chemicals are defined as those that present a physical hazard, health hazard, simple asphyxiant, combustible dust, pyrophoric (spontaneously ignitable) gas, or other hazard not otherwise classified. Common chemicals used in the brewery include acids, caustics and cleaning supplies.

The primary components of the program should be:

• Chemical labeling and other forms of warning, such as door signs

• Availability of Safety Data Sheets, or SDSs (formally known as Material Safety Data Sheets)

• Provision of employee information and training

• Proper Personal Protective Equipment (PPE)

Identification of Hazardous Chemicals

Identification of hazardous chemicals is the chemical manufacturer and importer’s responsibility, per OSHA 1910.1200. As end users, we rely on labels, safety data sheets (SDSs) and Globally Harmonized System (GHS) symbols to recognize hazardous chemicals, along with their specific hazards and controls.

Safety Data Sheets

Safety Data Sheets (SDSs) are the cornerstone of Hazard Communication Programs. SDS receipt, use, and organization are critical to the success of staff in gaining knowledge of chemical hazards, proper precautions, and good chemical hygiene practices.

1) SDSs must be readily accessible to all employees when they are in their work areas

2) SDSs may be stored in paper form, or may be stored electronically, as long as no barriers to immediate employee access are created by either option.

3) If employees use multiple work locations, the SDSs may be kept in the primary location, so long as employees have access to information, especially in an emergency.

Employee Information and Training

Hazard Communication training is required at time of initial assignment, and whenever a new chemical hazard is introduced into the work area. Documentation of employee training must be maintained at the brewery, or readily retrievable in the event of an OSHA inspection.

Who Must Be Trained

All employees, staff, faculty, and principal investigators, and affected individuals who work with or around chemicals must receive training. “Affected individuals” are considered to be those persons whom are using, exposed, or possibly exposed to hazardous chemicals during the course and scope of their job duties.

Proper PPE

Having the proper PPE for the job is of the utmost importance. At a minimum most breweries are going to want to keep chemical resistant gloves, first aid kits, eyewear such as goggles or face shields, hearing protection including earplugs or earmuffs and have eye wash stations or safety showers. Depending on the situations more involved PPE such as hard hats, respirators or even full body suits might be required. A little studying will help you determine what PPE will be needed for your particular brewery.

Now What?

So there’s a quick rundown of the requirements to help implement a Hazard Communication Plan to keep your employees safe, healthy and happy. There are a plethora of tools out there to help you get your plan together, including the OSHA website. Here’s a couple links to some helpful info to help get you started:

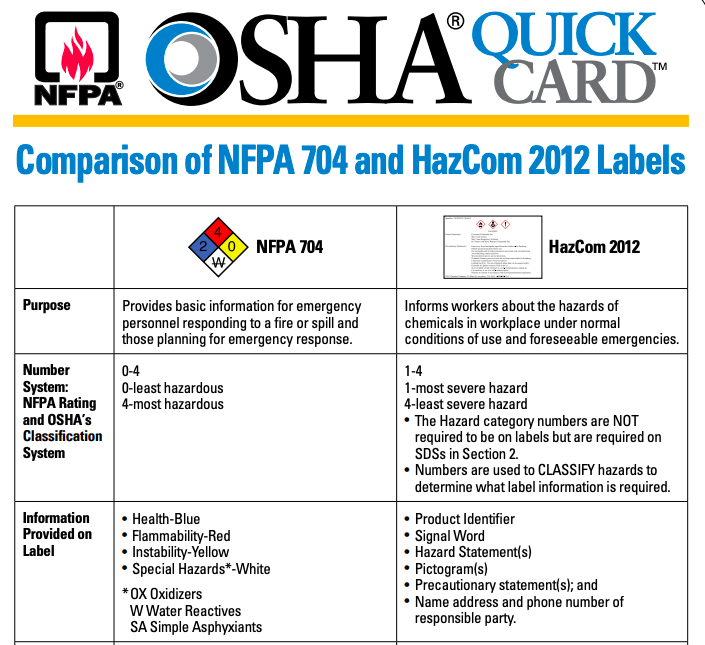

OSHA / NFP Quick Reference Card

Good luck, and here’s to a safe year in the Brewhouse!