To produce sour beers in a cost-effective and scalable way, brewers are increasingly turning to ‘Kettle Souring’. This is particularly true as canned sour beers gain a foothold in the market (beginning with early adopters like Anderson Valley’s Gose in California and DESTIHL’s Wild Sour Series in Illinois, but now abundant enough in Colorado to merit listicles in Westword). Despite this growth in the market, a number of brewers are hesitant to start their own kettle sour program – our goal here is to demystify the process by looking at the various techniques used by brewers of award-winning kettle sours.

First, some definitions. For our purposes, a sour beer is one to which the brewer intentionally adds a non-yeast microorganism that produces lactic acid, in order to create a tart or acidic flavor in the finished beer (generally a pH of 3.4 or lower, though titratable acidity and total acidity may be used as measures instead). This article specifically deals with souring wort in the kettle, as opposed mash, fermentation, or barrel-aged souring. Furthermore, the article will discuss fast souring (within 48 hours), not a slow or sour-aging procedure. Resources for these are included below, if you are interested in these techniques.

Next, let’s identify the benefits and potential problems of kettle souring (some of which may be overcome). The main benefit to kettle souring is a greatly reduced risk of contamination compared to other souring techniques, as the souring bacteria are killed during the boil prior to the heat exchanger and fermentation / packaging equipment. Additionally, kettle souring is fast – a sufficiently tart wort can be made in as little as 12 hours, and rarely will take longer than 48. However, brewing at a lower pH does impact a number of processes, for better or worse. A low mash pH increases protein removal from the grain and reduced astringency from the grain, but also impacts the effectiveness of mash enzymes (notably α- and β-amylase). As the wort sours overnight, if the pH is above 5.0 initially, the lactic acid bacteria will attack foam-stabilizing proteins and reduce head retention in the finished beer. During boil, a low pH reduces isomerization rates of α-acids in hops, as well as the solubility of humulone, and reduces color pickup from the Maillard reaction. Also, protein coagulation is most in pH range 5.2-5.4, so this is reduced in the boil (offsetting the gains from low mash pH). In fermentation, the acidic environment lowers yeast viability, but increases the rate of VDK conversion and removal (good!). Post fermentation, the use of silica-based clarifying agents is reduced below pH 3.8, and pH below 4.0 decreases flavor stability by allowing for greater formation of superoxide radicals (which eventually lead to the creation of E-2-nonenal (f.k.a. trans-2-nonenal) – the effect of this can be greatly decreased by limiting metal ions in the beer (copper, iron, etc.)

Now, the process. Souring a beer starts with the grain bill. A number of brewers select to include acidulated malt in their recipe for a sour beer – to be clear, this is NOT the souring agent, but lowers the pH enough to provide some protection against undesirable organisms, as well as preventing foam degradation. To achieve a pH of 4.5, roughly 5% of the malt should be acidulated. If the Mash pH is lowered using acidulated malt below the optimum range for α- or β-amylase (5.4-5.6), a longer mash rest may be needed to achieve full conversion of starches. If it is substantially lowered, a lower mash temp (140ºF-149ºF [60ºC-65ºC] vs 145ºF-158ºF [63ºC-70ºC]) is recommended to prolong activity of β-amylase. Acidulated malt is NOT required, however – mash may proceed as normal without acidulated malt to simplify the process and limit the impact of pH on the mash. As mentioned above, a low kettle pH limits color pick up – more colored malt may be added to counteract this effect. Lastly, additional Ca2+ ions may be added to prevent a pH rise during mash, vorlauf, sparge, and lauter (gypsum is recommended). The vorlauf, sparge, and lauter may proceed as normal, regardless of the grain bill. An alternative to using acidulated malt is dosing with exogenous lactic acid after the mash (vorlauf, sparge, or kettle).

Next is the most crucial step in the process, and the point at which kettle souring differs most from a standard batch – overnight souring with bacteria. This may be achieved a variety of ways: bacterial culture from a commercial provider, culture from a previous batch, addition of fresh grain, addition of a live culture from greek yogurt or another source, or a combination of these. Prior to pitching the bacteria, the wort must be prepared, and here again there are a variety of techniques. It is recommended that the wort first be flash-boiled for about 5-10 minutes to kill off any organisms that have survived to this point, as well as to drive off oxygen that has been introduced (to help protect against unwanted secondary infections) – a handful of brewers omit this step, increasing risk of unwanted contamination. Following this boil, the wort must be cooled down to roughly between 95 – 115ºF (35-46ºC) to incubate the lactobacillus, depending on the strain (a cooler temperature WILL increase the souring time). This is easily down by running the wort through the brewhouse heat exchanger – sanitizing is recommended, though the hot wort should provide protection against unwanted infection. During this time, CO2 may be added on top of the wort (or bubbled through) to create a ‘bed’ on top of the wort to further prevent aerobic bacterial infection. Alternatively, another jacketed vessel (fermenter, wort receiver, etc.) may be purged with CO2 and the wort transferred into this vessel instead of tying up your kettle.

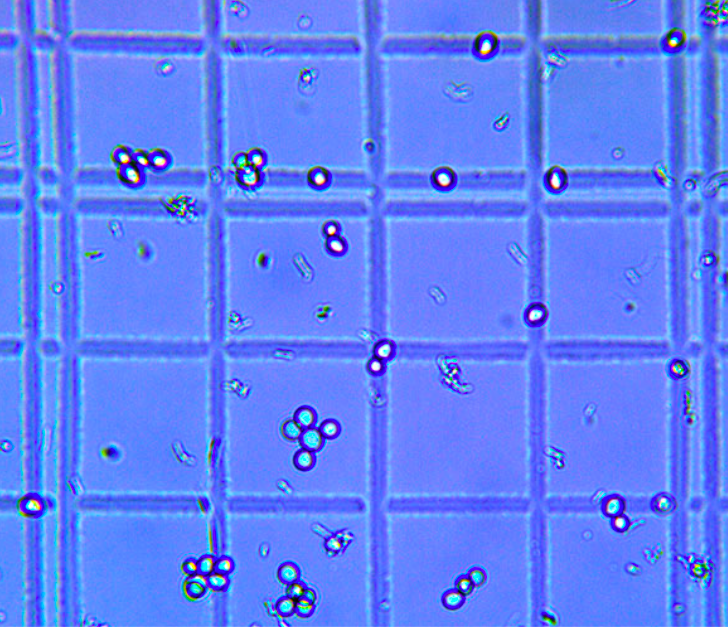

Once the wort is cooled, the lactic acid bacteria may be added. Prior to pitching, food-grade lactic acid may be added to aid in foam stability, if acidulated malt was not used or not used in high enough quantity (the lactobacillus will not effectively produce proteases that break down foam proteins below pH 5.0). If using a commercial provider of lactic acid bacteria, follow the pitching rate and temperature they recommend. If using a previous pitch, use the previous standards. For fresh grain, roughly 2L (roughly 2.5 lbs or 1.15 kg) of grain per 10/bbl in a mesh bag held at 115ºF (46ºC) will drop pH from 5.2 to 3.2 in about 14 hours. For other methods, between 100ºF-118ºF (38ºC-48ºC) may work. Try a starter batch in any case if you are uncertain. The target final pH should be between 3.0 and 3.5, depending on your desired sour taste (note: pH is a logarithmic scale, so a drop between 7.0 and 6.9 is 10 times the amount of H+ ions, though the perception of sour notes may not follow directly; additionally, there is substantial debate between the importance of pH in sour beers vs. titratable acidity or total acidity- see resources for the differences between these). In our beers, we use unmilled grain as the bacterial source – using a single supplier and 2L of grain / 10bbl, we achieve a pH of 3.2 in 14 hours consistently, though there is an increased risk of pediococcus infection using this method. Other brewers surveyed have incurred pedio infections using this method, and instead rely on commercial bacteria that they either propagate up in the week(s) prior to use, or harvest and repitch at a rate of ¼ to ½ bbl brink lacto per 20 bbl. In all cases, closely monitor pH following pitching and begin boil once the target has been reached. If pH drop is slow, or if souring a large vessel, recirculating the wort gently will make the reactions occur faster – just be sure to not add oxygen through this process.

During boil, due to the lower isomerization and solubility of hops, a slightly higher (~5-10%) hopping rate is recommended for hoppy beers. Additional gypsum or CaCl2 may be added to keep the pH low at this point as well. Mg2+ may also be added (epsom salt is recommended) to aid in isomerization – alternatively, pre-isomerized hop products may be used for bittering to circumvent this issue. To increase beer clarity, a higher dosage of kettle finings may be added due to the reduced protein coagulation at low pH – remember that these will not increase trub formation, but will instead increase cold break. These finings do not remove the protein, but will remove the polyphenols that the protein needs to bind with to create haze. Also, be aware that the large number of now dead bacteria will increase haze initially, but these should fall out of suspension during fermentation and cellaring. Towards the end of fermentation, closely monitor diacetyl levels (via sensory or other methods) – you may find your diacetyl rest is reduced in time, thanks to the VDK precursors’ faster conversion rate.

When knocking out, carefully monitor O2 addition to ensure adequate by not excessive levels – roughly 6L of oxygen per barrel has been reported, but this is highly dependant on setup, yeast strain, and gravity – higher gravity needs more oxygen. Experiment with slightly higher or lower oxygen levels if you are having slow fermentation or excessive off-flavors. With the lower pH, a 10%-45% higher yeast pitching rate has been reported, along with normal yeast supplements. It is not recommended that this yeast be reharvested, as the viability will be reduced.

During cellaring, a cold crash will be your best friend. Silica and isinglass finings effectiveness are reduced at low pH, and Brewer’s Clarex or similar enzymatic products are not well studied in sour beers. Papain-based clarifying agents will further reduce foam stability and are not recommended. PVPP and other filterable clarifying agents are also not well studied, though there is some evidence that the lower pH will increase the effectiveness of perlite as a diatomaceous earth alternative. Again, keep the beer cold (32ºF or 0ºC) for a day or two, and you’ll be fine – in my experience, this creates extremely clear traditional and dry-hopped sours (possibly due to co-flocculation with the dead bacteria). Filtration, carbonation and storage may proceed as normal.

Do you do anything differently? Did I miss something important? Want to bestow praise or condemnation? Questions, queries, or quagmires? Please leave feedback for this and any of our posts at: https://goo.gl/forms/lZqIJ09H7zSIEYqi1

Alan B. Windhausen

Lead Brewer, Pikes Peak Brewing Co.

Sources / Resources

Web:

Matt “Dr. Lambic” Miller, “Fast Souring with Lactobacillus” Sour Beer Blog, 20 Dec 2014, sourbeerblog.com/fast-souring-lactobacillus/

Matt “Dr. Lambic” Miller, “Lactobacillus 2.0 – Advanced Techniques for Fast SouringBeer” Sour Beer Blog, 18 Nov 2015 sourbeerblog.com/lactobacillus-2-0-advanced-techniques-for-fast-souring-beer/

Various, “Wort Souring” Milk the Funk Wiki, 21 Feb 2018, milkthefunk.com/wiki/Wort_Souring

Various, “Lactobacillus” Milk the Funk Wiki, 21 Feb 2018 milkthefunk.com/wiki/Lactobacillus

Jonathon Shikes, “Eight Wild or Sour Canned Colorado Beers to Take on Your Wild Colorado Adventures” Westword, 26 May 2017 westword.com/restaurants/eight-wild-or-sour-canned-colorado-beers-to-take-on-your-wild-colorado-adventures-9094681

Various, “pH, Total Acidity, and TA Defined” Juice Grape, Musto Wine Grape Company LLC, 3 Jul 2013 juicegrape.com/support/articles/pH,_Total_Acidity,_and_TA_defined

Books:

Bamforth, Charles W. (ed.) Beer: a Quality Perspective. Academic, 2009.

Michael J. Lewis and Tom W. Young Brewing: Second Edition. Aspen Publishers, 2001.

Karl Ockert (ed.) MBAA Practical Handbook for the Specialty Brewer, Vol. 1: Raw Materials and Brewhouse Operations. Master Brewers Association of America, 2006.

Karl Ockert (ed.) MBAA Practical Handbook for the Specialty Brewer, Vol. 2: Fermentation, cellaring, and Packaging Operations. Master Brewers Association of America, 2006.

Interviews:

John Simms, Wynkoop Brewing Company. Email Correspondence. 13 Feb 2018.

Adam Osborne, RAR Brewing. Facebook Correspondence. 22 Feb 2018.

Rodney Hughes, Flora Hall Brewing. Facebook Correspondence. 22 Feb 2018.

Charles W. Bamforth, UC Davis Master Brewers Program. Lectures. Jan-April 2015.

Michael J. Lewis, UC Davis Master Brewers Program. Lectures. Jan-April 2015.