Intro:

One of the most common questions that we get from our customers is what are the best methods for storing yeast for reuse between batches?

When should yeast be collected?

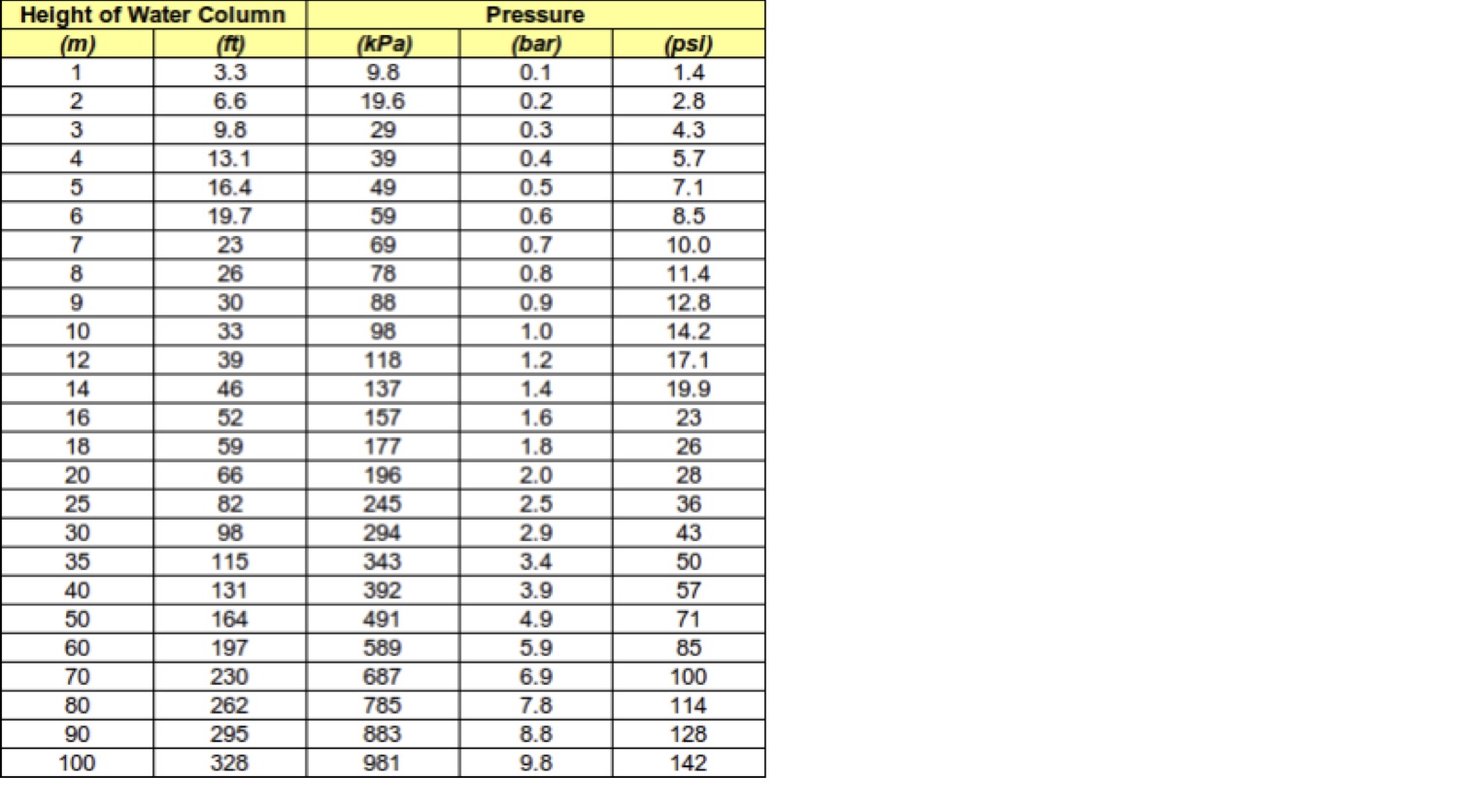

Yeast should be collected no more than 24 hours after being crashed in the fermenter. Conical fermenters help to collect yeast in cone so it can be harvested and re-pitched into a fresh batch of wort. However, this creates a somewhat inhospitable environment for the yeast to live in. First off, the yeast is starving since it has consumed most if not all of the fermentable sugars in the current batch. Second, through fermentation, the yeast has produced a significant amount of alcohol, which adds stress. Finally, pressure adds stress to the yeast, and it doesn’t have to come from the overall pressure in the vessel. Hydrostatic pressure from all the beer sitting above the yeast in the fermenter can lead to significant yeast viability loss. Anything over 2psi can begin to kill yeast over time, and this viability loss increases with increasing pressure and time. If we assume the density of beer is close to that of water (it’s slightly higher) then we can use the following chart to determine how much pressure yeast is being exposed to in a fermenter due to hydrostatic pressure. As you can see, anything greater than six feet is going to start to cause a problem, and the taller a fermenter, the greater the pressure.

Storage:

Now that you know that you should get the yeast out of the cone as soon as possible, what do you do with it? Well, the best thing you can do is get it into another beer as soon as possible. Cone to cone transfers are common, and brewers that use this technique are able to get many generations from a single pitch of yeast. The only issue with doing this is that you need another beer to immediately transfer the yeast into now that it is crashed, and the brew schedule doesn’t always allow for that. In this case you need to transfer the yeast into a sanitary vessel to be stored until it is needed. It is also best to feed the yeast a little sterile wort during storage so the dormant yeast doesn’t starve to death. Even yeast that is at 38°F can slowly metabolize sugars, and will be healthier if some are present.

Yeast Brink:

Although a yeast brink doesn’t need to be a masterpiece of sanitary stainless steel engineering, the more clean and sanitizable the vessel is, the better. Cross contamination in a yeast brink can be a huge issue since this yeast will be introduced to a fresh batch of wort directly from this vessel. Thus, anything in the brink is getting carried over to your next beer. Choosing a brink that has the least amount of locations for yeast and bacteria to hide in (valves, hoses, gaskets and agitator blades) will be the easiest to sanitize. I’ve seen many different versions of brinks, from collecting yeast back into the plastic vessels they were delivered in, too sophisticated jacketed, stainless vessels. The most common vessels for a small to midsized brewery are the converted half barrel kegs that can be handmade or purchased from multiple suppliers.

Vent your Brink!

The biggest issue I’ve seen in yeast storage is brewers that are worried about contamination from the environment, completely sealing off the brink and not allowing pressure to vent. You just went through all the work of pulling the yeast off the cone to avoid hydrostatic pressure, and now you’re going to kill it in the brink due to pressure built up during storage! Like I said before, yeast will slowly metabolize sugars even in the fridge, so giving it a way to vent is very important. This can be as simple as an airlock, or blow off tube into a bucket. Worst case, the brink will need to be ‘burped’ several times a day to avoid it building up beyond 2psi.

How long can I store it?

In biology, there is always an exception to every rule, but in general, you should be able to store yeast for at least a couple days, up to a week or so. I’m sorry I don’t have a hard and fast rule for this one, but the health of yeast in storage is based on several outside factors like strain type (some strains are hardier than others), health before storage (how healthy was the yeast at the end of the previous fermentation?), and storage conditions (how well does your cold room maintain temp?). The best way to know the answers to all these questions is to take regular cell counts, but that’s a rant best left to another post….

Written by John Giarratano at Inland Island Yeast. john@inlandislandyeast.com